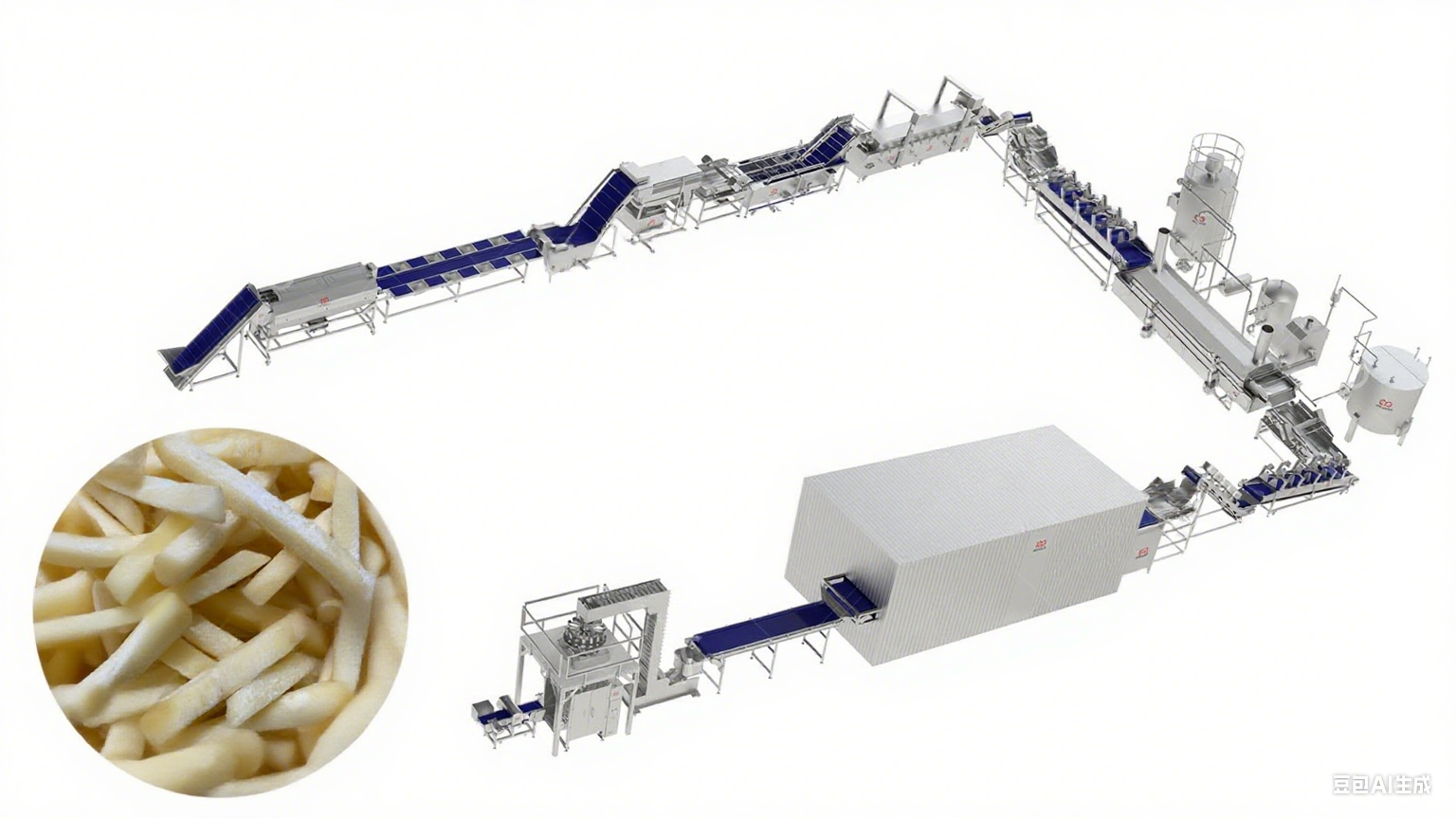

项目简介:The potato chips production line is a fully automatic food processing system designed for the efficient production of standardized French fries. It integrates multiple processes such as washing, cutti

Production Capacity100-5000kg/h

Working hours24/7

Belgium, a major global exporter of French fries, ships over 2 million tons of frozen fries to over 120 countries annually. In March 2025, the De Clercq family, based in West Flanders, the heart of Belgium's potato industry, decided to upgrade their traditional processing plant and ultimately chose a fully automated French fry production line from Foodline in China.

Intelligent Production Solutions

Max, our European Sales Director, presented the production line's core advantages in a video conference. After comparing solutions with suppliers in the Netherlands and Germany, the customer was ultimately impressed by the following features:

High Capacity: Processes 5 tons of potatoes per hour, increasing yield by 40%

Intelligent Sorting: An AI-powered vision system enables precise size grading (8mm/10mm/12mm)

Energy-Saving Design: A heat recovery system reduces energy consumption by 30%

Modular Structure: Supports future expansion with pre-frying/quick-freezing modules

Full-Lifecycle Service Guarantee

GoldenCrisp provides:

✓ 3D factory layout planning

✓ Local installation team

✓ EU CE certification support

✓ Annual maintenance package

"After introducing the GC-12, our defective rate dropped from 15% to 3%," Mr. De Clercq said. "The cost-effectiveness of the Chinese equipment far exceeded our expectations. In particular, the intelligent control system has shortened employee training by 60%."

免费预约考察现场可在线咨询免费预约考察现场或设计配置方案

在线咨询即刻联系我们 快速回复