Can produce snacks such as potato chips, french fries, banana chips, sweet potato chips, and sweet potato fries.

178371950397*24小时服务热线

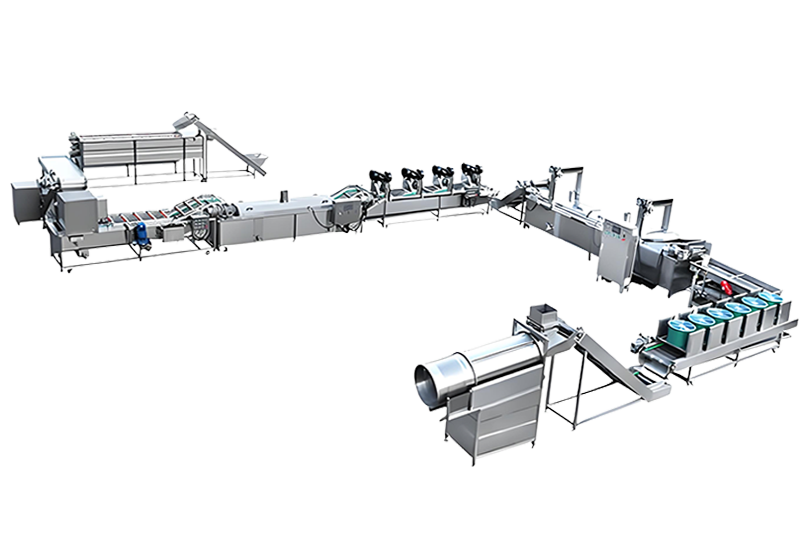

The French fries and potato chips production line operates fully automated and continuously, covering processes from cleaning, peeling, slicing, fermenting, blanching, dehydrating, frying, de-oiling, seasoning, to packaging.

50-1000kg/hr capacity:Choose your size! Full auto line from wash to pack. Save time & labor. Start chips fast!

Smart slicing & frying:Adjust thickness & shape. Dehydration cuts oil use. Crispy chips every time!

Safe & easy to run:Quick clean, no mess. One-piece seasoning tank. Less waste, more profits!

Quality checked before shipping:We test every batch. Reliable machines, trusted by chip makers worldwide.

Fully Automatic Potato Production Process:

1.PVC Elevator: For elevating and conveying fresh potatoes into the next washing peeling machine.

2.Potato Washing and Peeling Machine: Thoroughly washing and peeling the potatoes.

3.Sorting Conveyor: For manually disposing the uncleaned places and selecting the defective potatoes.

4.Fries Cutting Machine: Cutting the potatoes into fries,sizes adjustable from7*7 to 12*12mm.

5.Water Tank Elevator: Water as buffer to prevent fries breakage, and simply removing starch, meanwhile elevating fries into next step.

6. Fries Sorting Machine: Automatically picking up the small pieces fries

7. Bubble Washing Machine: Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch.

8. Blanching Machine: Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries.

9. Vibration Dewatering: Machine Through vibration to remove the surface water and also to transport the fries uniformly to the next machine.

10. Air Drying Machine: Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon.

11. Elevating Conveyor: For elevating and conveying the fries into next fryer machine.

12. Continuous Frying Machine: For quick frying the fries around 40 seconds in 180° oil to avoid the adhesion and extend the shelf life.

13. Vibration Deoiling Machine: Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine.

14. Pre - cooling Machine: Through high pressure wind blowing for pre - cooling and deoiling the fries.

15. Freezing Machine: Through mechanical vibration and wind pressure, the fluidized quick freezer floats products on stainless steel mesh belt, frozen products and prevent adhesion, achieve IQF.

16. Automatic Packing Machine: For packing the finished frozen french fries.

Foodline Machinery boasts 20 years of professional expertise as a leading Chinese manufacturer of high-quality food equipment. With an ISO-certified factory, we provide intelligent automated solutions to clients across six continents, catering to diverse applications from agricultural processing to industrial material handling. All equipment features durable construction and multilingual support. Our key advantages include customizable smart-sorting configurations, IoT monitoring systems, and standardized industrial interfaces, backed by lifelong technical guidance from our dedicated R&D team—factors that contribute to our 92% customer retention rate.

完善细致的服务流程7*24小时在线服务

7*24小时在线服务

2小时内给予解决方案

12小时内赶至客户现场

24小时内解决运转问题

在线留言您也可以在下面给我们留言,我们将热忱为您服务!

即刻联系我们 快速回复